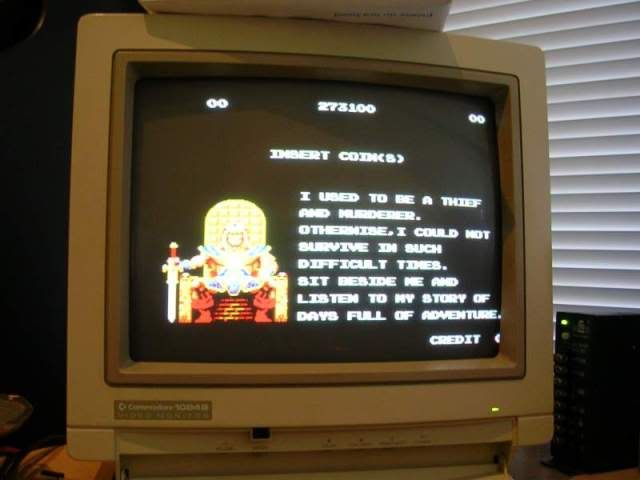

All in game sprites were missing too!

First thing to do is a visual inspection, looking for any damage, the board looked pretty mint, no gouges or scratched tracks, but a cap was missing from the amp section, which someone had labelled with a black arrow in texter...

..and someone had removed and replaced a couple of TMM2018 SRAM chips from a bank of 4, IC2 and IC3 were still soldered on the board, whereas IC4 and IC5 not..

..they had been desolded, and fitted into sockets made out of cut up parts of other sockets. Sadly whoever didn't use a chip to get the spacing right so the halves were wonky and the chip legs had to go down the outside of the contact pad bending the socket fragments and the chip legs at the same time.

Also on removing the two chips from their makeshift sockets it was obvious that one had lost half its ground pin...

...presumably because 5V and ground pins are often hard to desolder due to the amount of copper attached to them wicking the heat away so quickly the solder never fully melts.

The remains of the leg were just long enough to look like it was a normal leg in the socket, but not long enough to actually make contact.

On removal of the half sockets them more damage was evident...

....pin 21 on the lower chip had ripped the plate through hole out of the board, breaking the connection to that pin. The pin is actually the WE (write enable) pin which allows the board to tell the chip to go into write mode, as opposed to read mode, without this pin the CPU can never actually store data in the chip.

A quick buzz round with the continuity beeper confirmed that this was the only borked pad so I fitted a couple of sockets. As there was no plate through hole to solder pin 21 to I fitted a wire link to the nearby via where the original track had run.

Fixing the leg on the 2018 chip was simple too, I trimmed the thin end of the broken leg, put the chip into a machined pin socket and inserted a pin cut from a faulty chip in my bin into the socket hole. One this was lined up properly and pushed into the socket firmly I soldered it to the tag left on the original leg. On removal from the socket it is actually hard to tell its been patched up. As the chip was now usable I could test it with its pair in my EPROM reader and both chips passed the test.

So I put them back on the board..

..and powered it up, everything was perfect again, the graphics artifacts were gone and all sprites were back.

At this stage the game was working fine, the sound was good too, but the missing cap was included in the design for a reason, its there, along with a 0.1uF polyester cap to filter power supply hum on the 12V rail, so it needs to be there.

I tracked down the schematics and confirmed what the missing cap should be, a 1000uF 16V, and I had a spare from a scraped TV board. I removed the remains of the original cap legs, cleaned the black texter arrow off the board with some acetone and fitted the "new" cap in place...

...it looks like the cap is bulging in this photo but its actually perfectly flat, just the flash I think.

The game has been running in my cab for over an hour now without any issues at all.

I did originally wonder why those two chips had been replaced as they looked like they were the original chips, as they were almost identical to the other pair in the bank of four. Also as the only fault was the damage done during their replacement it begged the question why they were replaced in the 1st place. But on closer inspection the batch number of the pair differ from the ones still on the board, so the original ones probably were the cause of the fault, the previous repairer just made things worse while tying to replace them and probably just gave up.